FM 10 / 14

- Ideal for all shirt fabrics (FM 10) and outer fabrics (FM 10/14)

- Feeding belt 1400 mm (55.12 inch), for long parts

- Seperate feeding and transport belts, “cool feeding”

- Special insulation, little heat radiation

- Upper and lower heating individually controlled, with temperature limiters (1000 mm – 39.37 inch long)

- Seperate heating zones selectable, TOP (shirt), BOTTOM (outerwear)

- Special speed-heat up function, for fast heating of the machine

- Optional air and compression cooling

- Short (800 mm – 31.50 inch) or long (1400 mm – 55.12 inch) cooling belt

- Failure diagnostic system

Advantages:

- Consistent fusing results due to consistent pressure over the entire operating width

- Optimal fusing thanks to exact temperature control directly at the belt

- Optimal adjustment of pressure system (soft, medium) and heating sequence (top, bottom) to the materials to be processed

- Perfectly designed service concept allows easy and regular cleaning of machine

- Lowest possible energy consumption

- Consistent fusing quality due to optimized cleaning of the belts both on the inner and the outer side. Consequently, major reduction in soiling of roller and fusing material

- Reduced wear and tear of belt through contact-free belt control

- Visibility and accessibility: Improved access to stripper due to reduced machine width in the area of the cooling belt – Optimised viewing window for better visibility of the goods

- Functionality: A Removable FE for uncomplicated installation in confined spaces – Start-stop function of the input belt in case of deviation from the set fusing parameters

- Ergonomics: Weight savings on side panels for easier maintenance – Reduced basic machine height – Easy access to power supply – Reduced ambient temperature due to separate and cool input belt

- Control: Capacitive touch display for easier operation – User-optimised user interface – Diagnostic and remote service capability – Rotatable and tiltable display

The most productive solution for outerwear

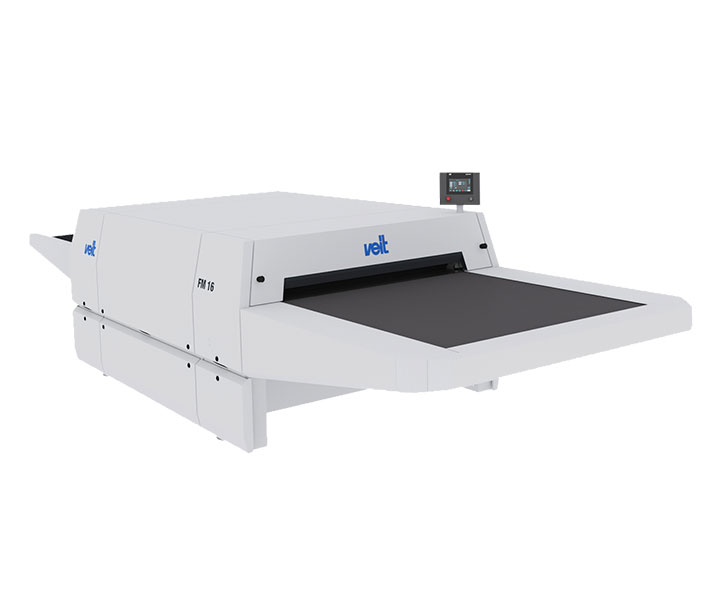

FM 14L / 16

Benefits as for FM 1000/1400, plus:

- Ideally suited for coats, winter fabrics and block fusing

- Extended heating zone, increased productivity (length 1400 mm – 55.12 inch)

- Three heating zones, more gentle heating

- For large-scale production or centralised fusing

- Ideal for combination with feeding systems (FE-L, ET)

The control panel – Never before has a fusing machine been so easy to operate.

Focussing on the essential and combining it with an intuitive operation – these have been our goals in designing the new 7“ colour touch screen control panel.

All the relevant fusing parameters are available at a single glance on the modern, user-friendly display. In the event of a parameter digressing from the pre-set values, say temperature is too low, the font colour turns into red and the feeding belt stops further feeding into the machine.

The integrated web server allows the VEIT Remote Service to diagnose the machine remotely.

- Language selection

- USB port for printer or for making programme copies

- Diagnostic system for the proper functioning of heatingelements, compressed air supply, belt running, error log

- Shift Management

- Remote Service

- Capacitive touch display

- IO Link connection

- Integrated OPCUA server

All the relevant fusing parameters are available at a single glance on the modern, user-friendly display:

- Set temperature of first heating zone

- Actual value of first heating zone

- Contact pressure of first pressure system displayed in bar or N/cm²

- Belt speed in m/min and seconds

- Stand-by function for energy-saving during breaks

- Heating on/off

- Cool-down function for cooling the belt and cleaning

- Actual value of second heating zone

- Set temperature of second heating zone

Ergonomics and Visibility – Everything in view and easy to reach

In the design and construction of the FM/LM series, particular attention was paid to further optimising the ergonomic wishes of our customers.In addition to reducing the basic height of the machine series, the important points for the production process were made more acces-sible and visible.The area of the transfer from the FE to the conveyor belt was adap-ted so that the materials can be better observed during the transfer. This helps to prevent misfixing.

The enlarged rear flap allows a clear view of the stripper and the transfer to the cooling belt, and thus an immediate visual check of the fusing results. In combination with the reduced machine width in the area of the cooling station, accessibility to the stripper has been made much easier.

Reviews

Clear filtersThere are no reviews yet.